Although i haven't been making furniture for that long, i have made and used more jigs and aids in the past year, than the few years i have been training to make furniture. Making and using jigs can be one of the most useful things you do while you are making furniture.

A jig is a workshop made tool or aid which will help you perform a specific task repeatedly and efficiently. They can come in all shapes and sizes and serve a wide variety of purposes. Below are examples of jigs and aids which i have made and used over the past years.

Although in initially it may take a while for you to design and make the jig, but in the long run, the time spent making the jig will benefit you when making the piece of furniture.

A jig is a workshop made tool or aid which will help you perform a specific task repeatedly and efficiently. They can come in all shapes and sizes and serve a wide variety of purposes. Below are examples of jigs and aids which i have made and used over the past years.

Although in initially it may take a while for you to design and make the jig, but in the long run, the time spent making the jig will benefit you when making the piece of furniture.

A bench hook is a simple yet very effective jig. it consists of three pieces of wood in a certain arrangement which allow the board to hooked overt the edge of you workbench, allowing you to place your work piece against a fence to make a square cross cut.

Another jig which is very useful in conjunction with a bench hook is a shooting board. A shooting board allows you to perfectly square up ends of boards with a hand plane. The hand plane runs on a a bed at 90 degrees to a fence.

Here is a close up shot of a plane and a shooting board in action. The workpiece is places up against the fence and the hand plane runs along the bed slicing very thin end grain wood shavings off.

This jig was one of the jigs i have made and i wish i have made one years earlier.

This jig was one of the jigs i have made and i wish i have made one years earlier.

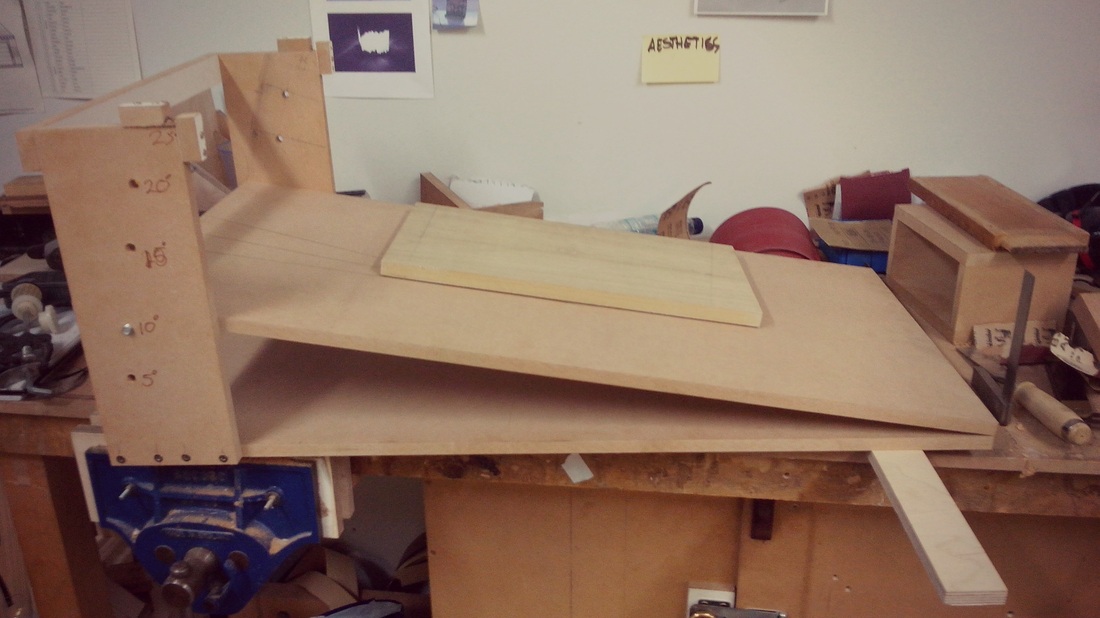

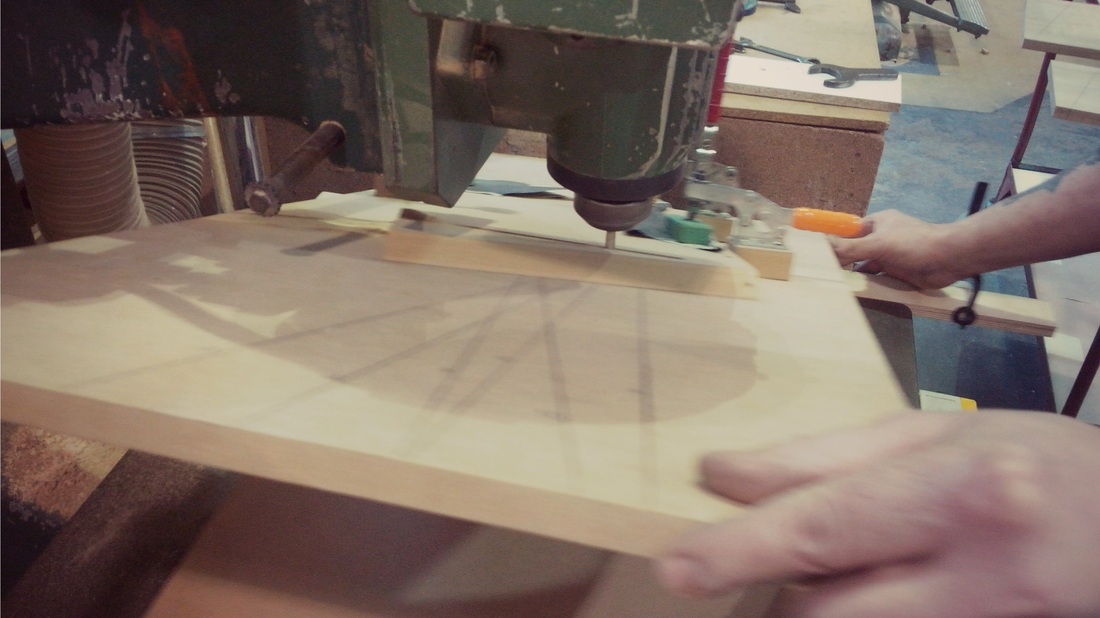

Above is a jig which i made to be used on an over head router to allow me to create multiple compound angled through mortices. The jig runs along the bed of the over head router. The cutter is then lowered in to the workpiece which is clamped down on the the angled bed of the jig. The jig is then slid forwards and backwards, dropping the head each time cutting thought the work piece.

Above you can see how the over head router works and how the jig works with it. The workpiece is toggle clamped in place preventing in from moving while the router is cutting.

Above is large jig which helped me create a side table, a blog post will be up soon about it. The jig held all of the shelves in the correct place in space. I then steam bent some 6mm thick oak slats which then went through the corresponding slots which gave structure to the piece of furniture.

Above and below was a test in which i steam bent an oak slat and then forced through the corresponding holes.

Above is a small jig which allowed me to create small trays repeatedly for a small project. The Pieces of plywood which are all cut to the same size and the wedged in place from the underside. Then a router with a guide bushing was the used running around the edge of the template creating the desired shape.

Above is a jig which i use for marking out dovetails. After cutting the tails i use this jig because in holds the two pieces at perfect right angles and also allows me to clamp my work enabling me to mark out precisely,

The jig is very simple, but very effective which allows me to precisely mark out my dovetails.

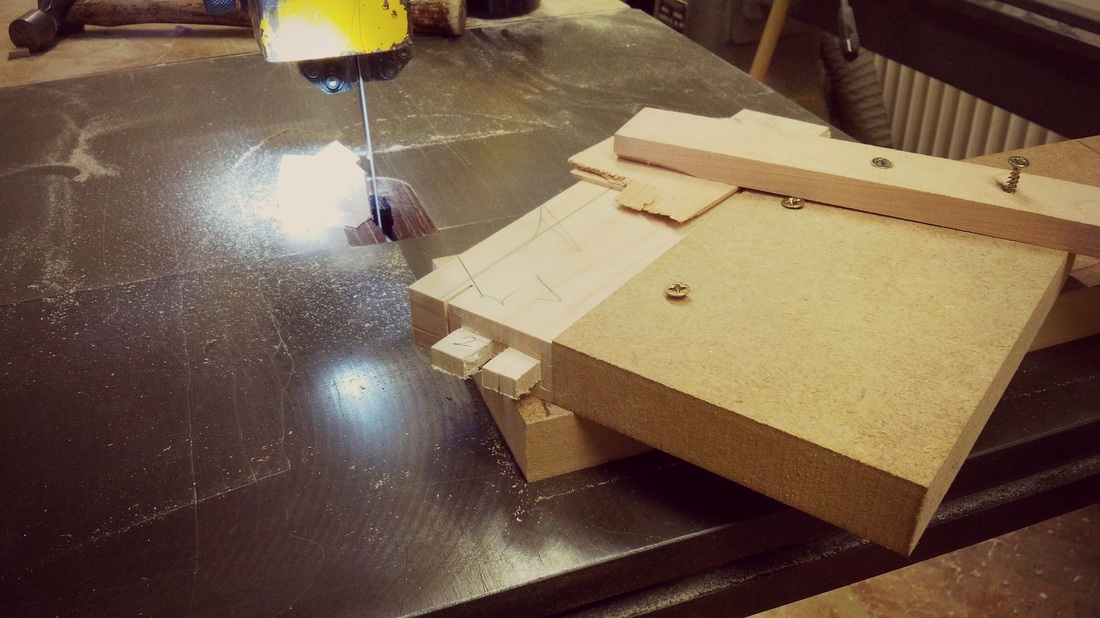

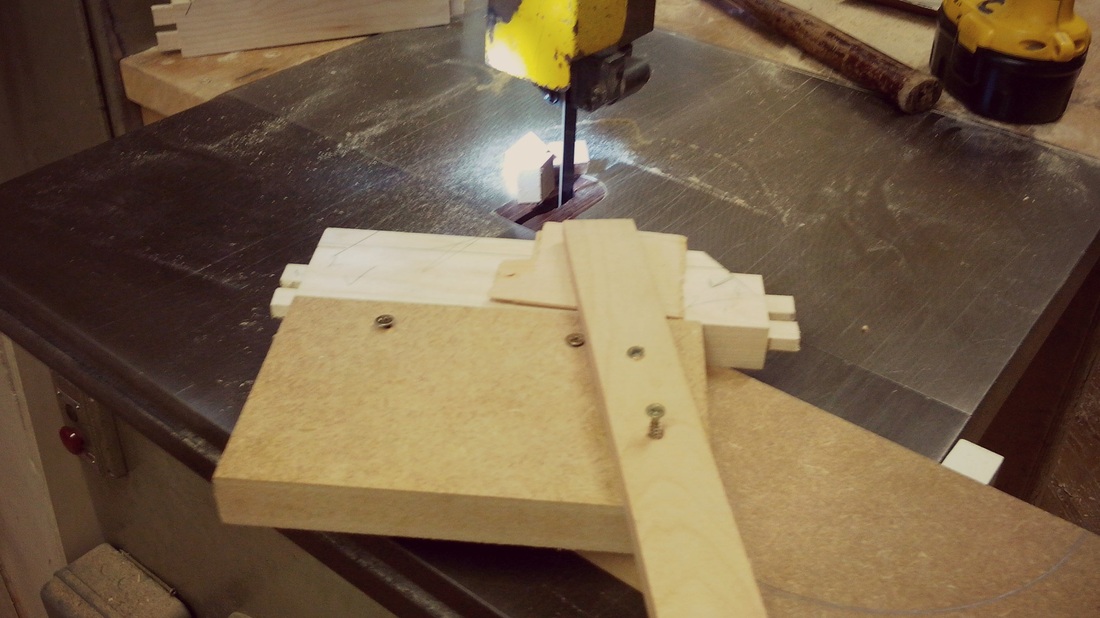

This final jig is very crude but it served the purpose of making and angled cut on the band saw. This jig runs along the side of the table allowing me to make a small straight relief cut.

To end, jigs don't have to be really extravagant pieces of work they could be simple pieces which allow you to perform specific task. Don't underestimate the use of a jig, they can massively help you do repetitive work easily and accurately

If you have any jigs you would like me to share or have any questions about jigs, please get in touch, i hope you enjoyed this and found it useful.

Josh Hall

If you have any jigs you would like me to share or have any questions about jigs, please get in touch, i hope you enjoyed this and found it useful.

Josh Hall